Dry rodded unit weight is sometimes called bulk or loose unit weight. To reduce costs concrete floors are seldom provided.

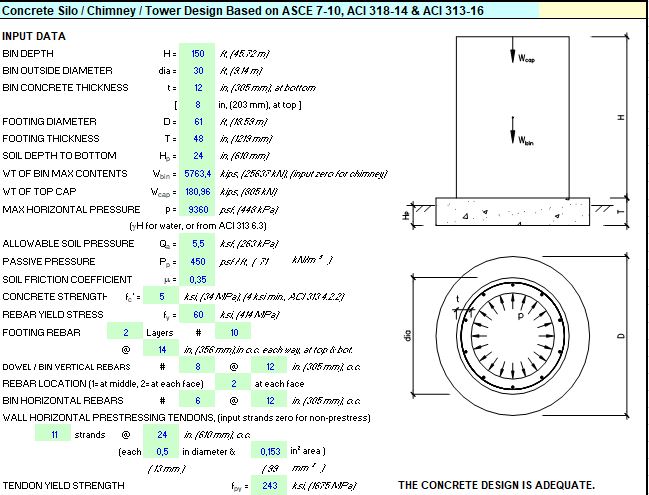

Concrete Silo Chimney Tower Design Spreadsheet

Water weight 32 gal x 833 267 Lbs wc 267 517 0516.

. Slipform silos are best for construction projects over 65 in diameter or if multiple concrete silos need to be created at once. First forms are erected according to the structural or architectural plans. Instructional Materials Complementing FEMA 451 Design Examples Foundation Design 14-20 Additive Combination Given P 234 k M 7258 k-ft Try 5 foot around thus L 35 ft B 10 ft Minimum W ML2 P 181 k 517 psf Try 2 foot soil cover.

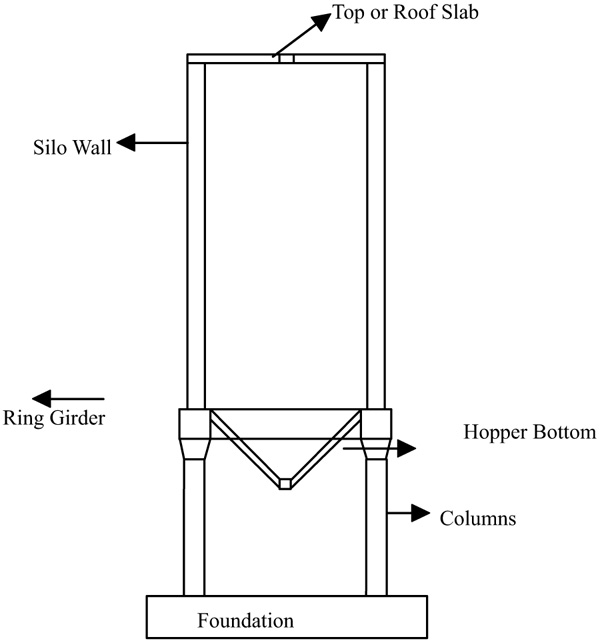

You need to design an economical RCC foundation comprising of 4 pedestals and a common raft. This design example focuses on the analysis and design of a tapered cantilever retaining wall including a comparison with model results from the engineering software programs spwall and spmats. The foundation of the silo may be mat raft or pile based on the soil condition.

Corrosion resistance of cement is poor so the cement storage silo should have good anti-corrosion then this cement container can be used for much longer time. Design calculations and AutoCAD drawings are required. The concrete foundations generally are 75 of the total silo cost including the steel silos.

An example of the. Design Calculation of Cement Silo. Loads from this column to the foundation are.

Reinforced poured concrete basement construction is a multiple step operation. The silo is prefabricated steel and has four legs. Stressstrain relationship of coarse RCA concrete exposed to elevated temperatures.

This Digest outlines the problem and indicates the need for a soil investigation to determine the allowable bearing capacity and compressibility of the soil and thus enable proper foundation design. A de-articulated foundation can cope with these variables far easier whether a raft solution is adopted or piling. Adopting German coiling technology which ensure the silo good sealing feature.

Jumpform silo construction projects range from 10 to 65 in diameter. To reduce costs concrete floors are seldom provided. The best solution for these silos is often a shop-welded tank.

The grade of concrete to be used is M30 and grade of steel is Fe415. JS 1 cubic Cement large capacity concrete mixer. The general arrangement drawing is attached for reference.

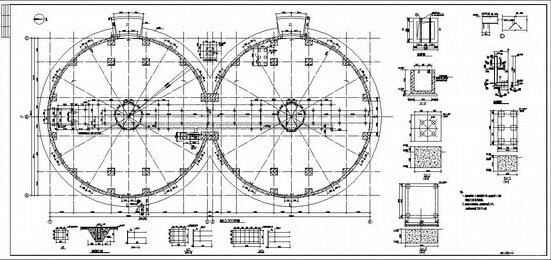

The cement silo was constructed immediately south of the B-silos and the new clinker silo refer to Fig. Structure General Arrangement 5. These concrete silos are formed from a continuous monolithic pour of the concrete walls necessitating a round-the-clock construction schedule.

To plan analyze and design various structural. Dry Rodded Unit Weight. Additional details-Weight of silo 10 MT - Weight of cement 100 MT.

Project design examples of shallow foundations Open PDF. The silos are premade. For additive combo use 12W Q max P 12W3L2 eB2 94 ksf.

As for the backfill I cant confirm whats beneath the gravel and sand backfill the fill is 3meter high. Isolated Footing Design Example. Barclays Bank building London England.

In many cases this transfer is either from steel column base plates to the foundation or from precast concrete members to the foundation. Dust removal design should be chosen according to the following parameters. The silos were made of steel.

141 are unpleasant for personnel nearby and can damage a silo structure. The anchors are designed to transfer the design loads from the superstructure to the foundation. Design Calculation of Cement Silo.

The highest groundwater table is expected to be 4 below grade. Shop-welded tanks will cover storage needs from zero up to about 10000 cu ft. View sample drawings of our lime storage silo fly ash storage silo and other designs.

620 x 0400 248 Lbs of water. The foundation of the silo may be mat raft or pile based on the soil condition. The general arrangement drawing is attached for reference.

EXAMPLE 10 - SIGN STRUCTURE FOUNDATION DESIGN 2 Larm 16 ft øpole-T 125 in esp 11 ft Darm 15 ft Hsp 6 ft Lsp 8 ft Lpole 22 ft øarm-E 625 in øarm-B 10 in Y øpole-B 155 in X Z Existing Ground Dshaft 13 ft øshaft 36. These same companies that have a need for bulk storage also have. Example 4 Determine wc given a mix design with 32 gallons of water and 517 Lbs of cement per yd.

1000 kN Uniaxial Moment. Cement silo foundation design example. Thus silo quaking and silo honking can affect the environment Fig.

Cement silo foundation design example. New design 15m3 double shaft concrete mixer. Over 30 years design working time.

Comprehensive Design Example 2. Design applications of raft foundations. Foundations for Bulk Storage Facility Problem The project consists of building several dry product storage silos near an existing rail siding in an open field presently used for truck parking and loading.

A structural engineer is necessary for the design of a reinforced poured concrete foundation. Let us consider an isolated footing for an RCC column of size 450mm x 450mm. 43 X 115 Lime Storage.

Cement clinker storage silo Rugby England. Many tower silos constructed on clay soils have ring-shaped concrete foundations. Primary Loads and Load Combinations 6.

They gave me a limited amount of data. New design twin shaft 1 yard concrete mixer. Best selling new design 2 yard concrete mixer.

To plan analyze and design various structural. The silo was constructed on a relatively stiff circular raft foundation 25 m in diameter to withstand a design average maximum bearing pressure of 300 kPa under static loading conditions. The silo drawings below are just a sample of the concrete storage silo designs done by Marietta Silos.

27 X 99 Lime Storage Silo 08-C253LGA01. The storage silo is an integral part of any business that has need for dry processing or solid handling as part of its normal operations. What I need to determine is the foundation.

Filter should not be less than 24 squares when the silo capacity is under 500 t above 500 t should choose according to the specific tonnage multiplied by the coefficient of 005. Hui Zhao Yuyin Wang. The retaining wall is fixed to the reinforced concrete slab foundation with a shear key for sliding resistance.

We design construct and repair storage silos for almost any industry. Next reinforcing steel bars are assembled within the forms and tied together. 100 kNm The safe bearing capacity SBC of soil is 300 kNm2.

Features of Cement Silo. Cement Silo Foundation Design Example - manufacturer factory supplier from China. Design of reinforced concrete silos were explained in Criteria for Design of Reinforced concrete bins for the storage of Granular and Powdery materials.

When the silos are filled. The new steel silos are to be 32-0 in diameter 75-0 tall and store 1000 tons of dry material. It is important therefore to.

Guide To Foundation Design Column Footings Civil Engineering Projects Column Design Rebar Detailing Foundation

Combined Pad Foundation Design Spreadsheets Comprise Of A Series Of Spreadsheets Which Can Be Used For S Concrete Design Building Foundation House Plan Gallery

A Simplified Approach For Analysis And Design Of Reinforced Concrete Circular Silos And Bunkers

Steel Column Footing Foundation Detail Steel Columns Footing Foundation Steel

Design Of Reinforced Concrete Foundations Civil Engineering Design Concrete Footings Civil Engineering Construction

Pin By Muhammed Mahmoud On حاجات جامده Foundation House Construction Plan Pile

Design Calculation Of Cement Silo Civil Engineering Downloads

Concrete Silo Concrete Silo For Sale Concrete Silo China Supplier Concrete Silo Factory

0 comments

Post a Comment